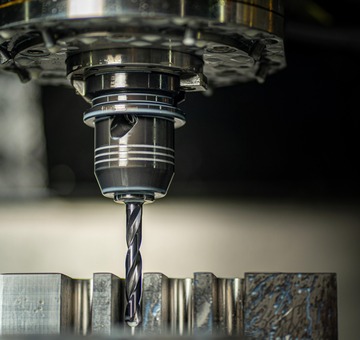

Problem Statement

Unavailability of accurate and up to date WIP data may lead to inefficient production planning. It could also lead to pilferages and rejections being improperly accounted for, thus distorting costs and pricing.

How sfHawk helps?

- The real time machine data that sfHawk collects can easily provide production count by individual machines in the line as well as WIP between the machines.

- If individual components are tagged, sfHawk can provide granular, component-level and part-level traceability of WIP from stores till the end of line.

- It can also track rejection at the level of individual machine/line/operator.

Benefits

- More accurate tracking of WIP data, leading to streamlining of supply chain.

- Superior visibility of material flow and WIP creates and sustains a culture of accountability.

- Timely interventions to address the cause of rejection at the individual operation level.