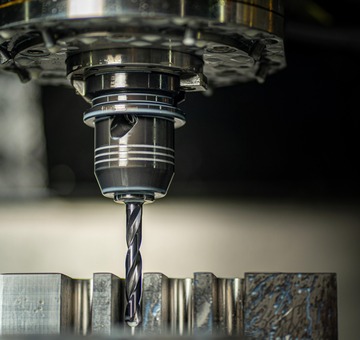

Problem Statement

High dependency on supervisors and operators for managing production scheduling typically results in greater loss of time between setups.

How sfHawk helps?

Once sfHawk receives the daily production schedule from the scheduling system, it keeps track of batch sizes and monitors production. Additionally, it also:

- Intimates the warehouse ahead of time to deliver the raw materials needed at the machine for the next batch.

- Alerts the setter ahead of the time to get ready for setting up the next part.

- Uses the auto CNC program transfer feature to reduces the risk of error by the setter.

Benefits

- Reduced human dependency improves process efficiency.

- Better coordination between various departments makes setups more efficient and reduces wastage of time, thereby enhancing overall productivity.

- Better inventory management through automated monitoring of batch sizes.