Enhancing Machine Uptime with sfHawk: A Smart Factory Solution.

In the fast-paced world of manufacturing, machine uptime is a critical factor that directly impacts productivity and profitability. Every minute a machine is down, your production schedule, efficiency, where sfHawk comes in—a smart factory solution that not only enhances machine uptime but also optimizes overall equipment effectiveness (OEE), production quality control, and machine productivity.

The Importance of Machine Uptime

Machine uptime refers to the amount of time that a machine is operational and capable of performing its tasks without interruptions. High uptime is synonymous with high productivity, as machines are kept running smoothly and efficiently, reducing the need for costly repairs and minimizing delays in production. However, achieving consistent machine uptime requires a sophisticated approach to machine monitoring and maintenance.

How have Smart Factories helped in the US?

Over the past decade, the manufacturing landscape in the United States has undergone a significant transformation, largely due to the adoption of smart factory solutions. These technological advancements have led to remarkable improvements in machine uptime across various industries.

A notable 2021 report by Deloitte shed light on this trend, revealing that manufacturers who implemented Industrial Internet of Things (IIoT) solutions experienced substantial benefits. These solutions, which include real-time monitoring and predictive maintenance capabilities, resulted in an impressive reduction in downtime – up to 25% in some cases.

The impact has been particularly pronounced in sectors where machine uptime is crucial, such as automotive and aerospace. In these industries, companies leveraging smart factory technologies observed a 15% increase in overall equipment effectiveness (OEE). This metric is a key indicator of production efficiency and reliability.

What’s driving these improvements? The answer lies in the integration of cutting-edge technologies. Advanced sensors, artificial intelligence-powered analytics, and cloud platforms work in tandem to provide real-time insights into machine performance. This allows for proactive interventions, effectively minimizing unplanned failures and optimizing production processes.

In essence, these smart factory solutions are revolutionizing the way manufacturers approach machine maintenance and productivity. By enabling data-driven decision-making and predictive capabilities, they’re helping industries stay ahead of potential issues and maintain peak operational efficiency.

How sfHawk Boosts Machine Uptime

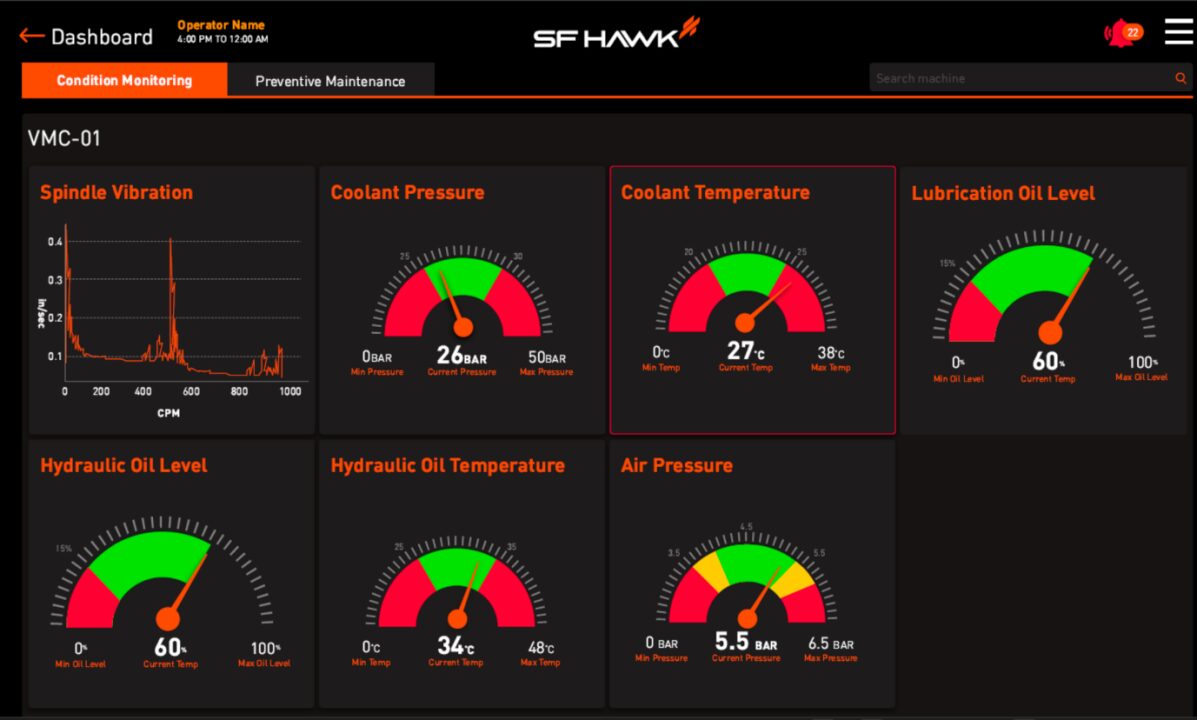

sfHawk’s cutting-edge machine monitoring system offers real-time insights into your machines’ performance. By continuously tracking and analyzing critical parameters such as machine health, operator efficiency, and tool conditions, sfHawk helps prevent unexpected downtimes and enhances productivity.

-

- Predictive Maintenance: With sfHawk’s smart sensors and data analytics, you can implement predictive maintenance strategies that forecast potential machine failures before they occur. This proactive approach significantly reduces unplanned downtime, ensuring that your machines stay operational longer.

-

- Real-Time Monitoring: sfHawk provides live updates on machine status, allowing you to address issues as they arise. This real-time visibility into your shop-floor operations means you can take immediate action to resolve any potential problems, ensuring maximum uptime.

-

- OEE Optimization: Our platform is designed to optimize OEE by balancing machine availability, performance, and quality. By improving uptime and reducing cycle times, sfHawk enables your factory to achieve higher OEE, translating into more efficient production and better quality control.

-

- Improved Production Quality Control: Uptime isn’t just about keeping machines running—it’s also about maintaining consistent production quality. sfHawk’s intelligent monitoring ensures that machines are operating within optimal parameters, minimizing the risk of defects and ensuring that your products meet the highest standards.

Predictive maintenance with sfHawk

sfHawk offers a comprehensive preventive maintenance solution designed to optimize machine performance and reduce downtime in manufacturing environments. This system integrates several key features to provide a holistic approach to equipment maintenance and monitoring.

At the heart of sfHawk’s solution is a central dashboard that offers both overview and detailed insights into maintenance tasks across all machines. This dashboard provides real-time visibility into completed and pending maintenance activities, allowing managers to quickly assess the maintenance status of their entire fleet. Users can easily track how many maintenance tasks have been performed on each machine and identify any overdue or upcoming tasks, ensuring that no critical maintenance is overlooked.

The system also incorporates advanced sensor and temperature monitoring capabilities. By continuously tracking various parameters, sfHawk can detect anomalies or trends that might indicate potential issues before they escalate into major problems. This proactive approach helps prevent unexpected breakdowns and extends the lifespan of equipment.

Another crucial feature is spindle load monitoring. This functionality is particularly valuable for CNC machines and other equipment where spindle performance is critical. By monitoring spindle load in real-time, sfHawk can alert operators to potential overloading or underperformance, helping to maintain optimal cutting conditions and prevent premature wear or damage.

Key pointers:

-

- Central Dashboard:

- Provides overview and detailed views of maintenance tasks

- Shows completed and pending tasks for each machine

- Enables quick assessment of fleet-wide maintenance status

- Sensor and Temperature Monitoring:

- Continuous tracking of various machine parameters

- Early detection of anomalies and concerning trends

- Helps prevent unexpected breakdowns

- Spindle Load Monitoring:

- Real-time monitoring of spindle performance

- Alerts for potential overloading or underperformance

- Maintains optimal cutting conditions and prevents premature wear

- Central Dashboard:

These features work together to create a robust preventive maintenance system, helping manufacturers minimize downtime, optimize machine performance, and extend equipment lifespan.

Why Choose sfHawk?

sfHawk isn’t just a machine monitoring system—it’s a comprehensive smart factory solution that empowers you to take full control of your production floor. By enhancing machine uptime, optimizing OEE, and improving production quality control, sfHawk helps you unlock new levels of efficiency and productivity.

In a competitive manufacturing environment, every second counts. With sfHawk, you can ensure that your machines are performing at their best, your production processes are streamlined, and your business is always ahead of the curve.

Conclusion

In today’s fast-paced manufacturing environment, every second of machine uptime counts. With sfHawk’s advanced smart factory solutions, you can minimize downtime, improve productivity, and stay ahead of the competition. Whether you’re aiming to boost your Overall Equipment Effectiveness (OEE) or enhance production quality, sfHawk gives you the tools to take full control of your operations.

Don’t wait until the next unexpected breakdown costs you time and money. Get in touch with our team today to schedule a demo and see how sfHawk can revolutionize your factory’s performance. Let’s work together to ensure your machines are always operating at their peak.