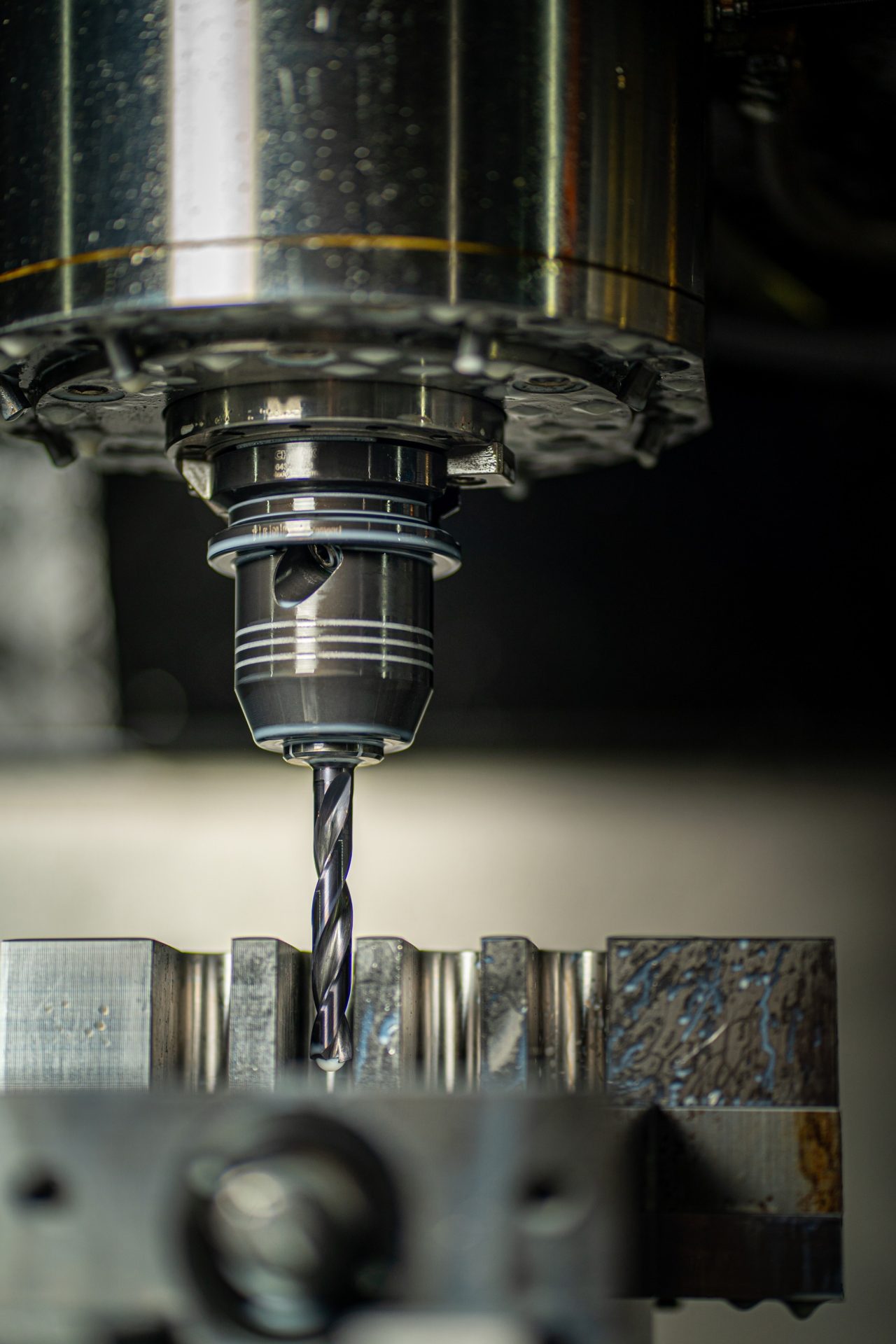

Problem Statement

While building the CNC program, it is not easy to determine if the machine is being loaded optimally.

This can result in under-utilization or reduced life. Also, for a given job, different tool options may be available; selecting the best tool through a comparison is laborious and time-consuming.

- While building the CNC program, it is not easy to determine if the machine is being loaded optimally.

- This can result in under-utilization or reduced life. Also, for a given job, different tool options may be available; selecting the best tool through a comparison is laborious and time-consuming.

How sfHawk helps?

- sfHawk collects data on numerous machining parameters in real time.

- This data can be used to provide the load profile of the cutting tool when the machine is running.

- This helps the engineer to balance parameters such as speed, depth of cut and cycle time so that load remains within the limits stipulated by the machine tool manufacturer.

Benefits

- Optimising cycle time without the risk of hampering machine health.

- Avoid need to invest in separate software tools just for this.