Problem Statement

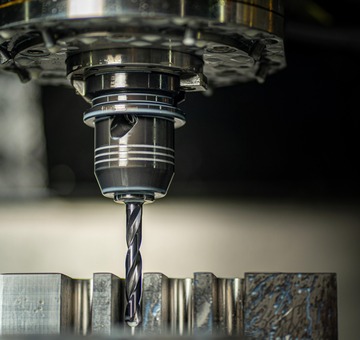

Unavailability of machining data/parameters for each part to analysis quality issues or recalls.

How sfHawk helps?

- In addition to collecting real time data on machining parameters such as speed, feed rate, tool ID, machine alarms, etc., sfHawk also allows integration of DM/RFID scanners to read the part ID.

- By linking each part ID with its machining parameters, sfHawk makes it possible to search for parts produced with a specific combination of parameters at any given point of time.

- This improves ability to analyse defects and identify root causes so as to find solutions.

Benefits

- Faster and more efficient response to rejections and product recalls.

- Data-driven resolution of quality issues.

- Reduced wastage and rejects, thus improving overall margins.